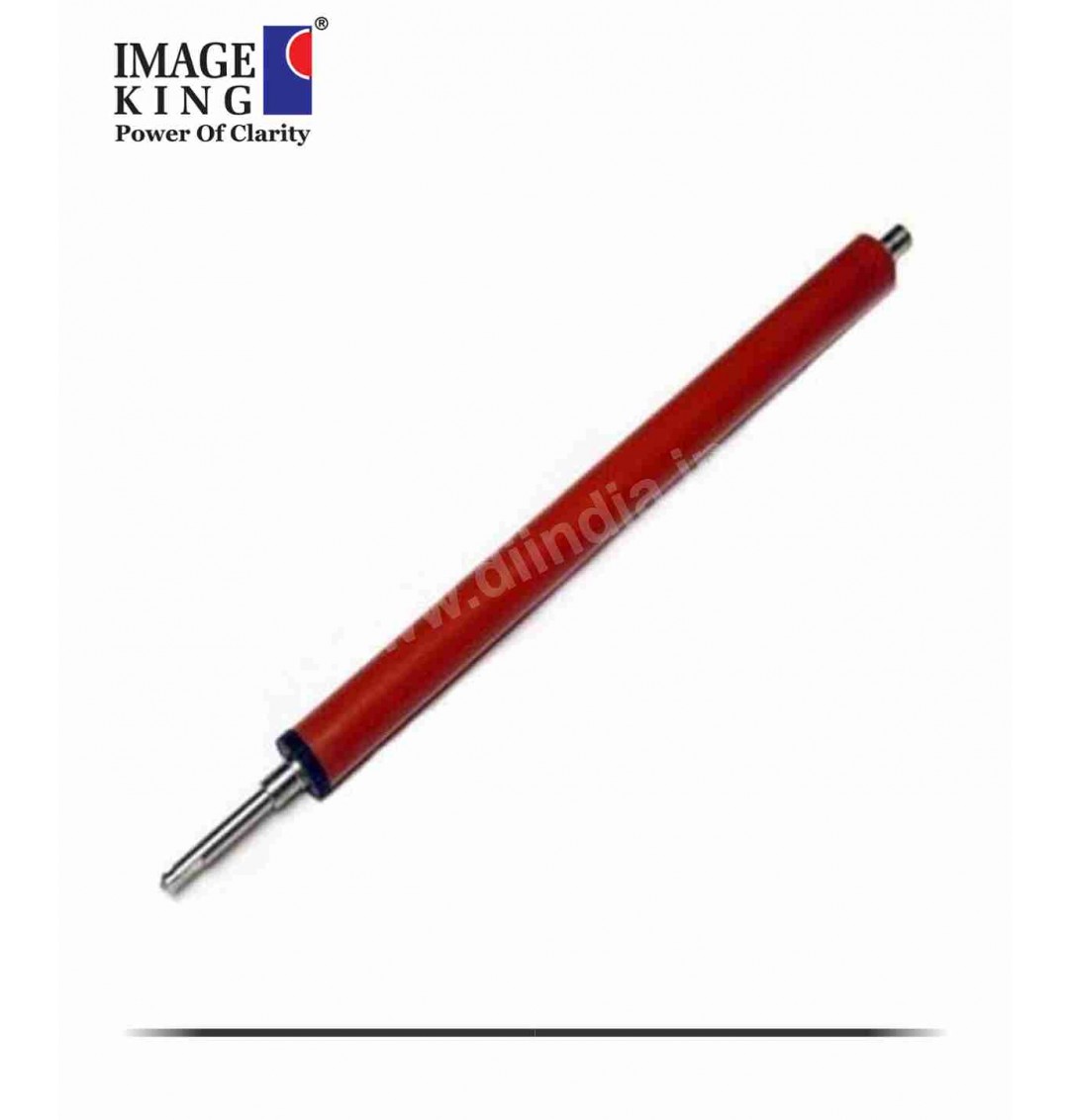

The Pressure Roller 88A is a component found in printers that use the HP 88A toner cartridge (HP part number CE285A). The Pressure Roller is a crucial part of the printer's imaging and printing process, playing a role in how the toner is fused onto the paper.

Key Features of the Pressure Roller 88A:

Functionality:

- The Pressure Roller is part of the fuser unit in laser printers and works in conjunction with the Fuser Roller to melt the toner powder onto the paper. The pressure roller helps apply pressure to ensure that the toner adheres to the paper's surface and that the image is properly transferred.

Add A Review

Your email address will not be published. Required fields are marked

Your Rating *

You need to Login OR Register